There are many tools that can assist one diagnosing dampness problems - some of them simple, others more sophisticated. Here are the most common ones we use on a daily basis:

1. Observation

Observation - especially if paired with considerable expertise and a thorough understanding of the underlying phenomena - can be a very valuable tool in diagnosing dampness problems. The look, color and texture of a wall can carry important information to those professionals who understand and able to interpret this information.

On the other hand, visual observation has also significant limitations, direct observation being limited to wall surfaces only, which very often behave very different from the depth of the wall fabric. To gather reliable information from under the depth of the fabric, various tools have been developed.

2. Electronic Dampness Meters

The most common way in diagnosing dampness problems are dampness meters.

Just like cars - not all dampness meters are created equal. There are many types of dampness meters and depending on how sophisticated they are, they can deliver very different results.

One of the most important quality parameter is of dampness meters is their penetration depth: the deeper a meter can detect moisture under the surface, technologically the more advanced and more costly it is. The opposite is also true: cheap damp meters can only measure humidity on the surface, while more advanced / expensive ones can measure further in depth.

There are 3 different dampness meter technologies in use today:

Resistance Meters

Resistance (Pin / Prong) Meter

They have two sharp pins (prongs) as they measure conductivity, measuring the resistance of the fabric between them - hence their name: resistance meters. Because damp materials conduct electricity more than dry ones, the meter can differentiate between various levels of humidity.

These meters have originally been developed to measure the moisture content of timber but they have extensively been used to measure the moisture content of masonry.

Due to their low cost (about £15-20) they became very popular. But having no depth penetration, being able to only detect surface humidity makes them unfit for professional diagnosis - yet they have been used for decades, still being used today.

Capacitance Meters

Capacitance Meter

Capacitance meters are a newer technology and they slowly started replacing old resistance meters. They only have one larger electrode, which sends a small current into the wall towards the ground, and based on the capacitance of the material (ability to store this energy) the meter will estimate the wall fabric's moisture content.

Being a more advance technology, capacitance meters are more expensive (about £100-200) and more reliable as they can penetrate about 20-40 mm in depth, giving a much more reliable diagnosis about the moisture content of the walls.

Microwave Meters (Radar principle)

Microwave Meter

Microwave meters are the latest technology developed recently, being still classed as emerging technology. They work on the principle of ground-penetrating radar: the shoot a microwave beam into the wall fabric reading its reflection. As damp areas absorb microwaves beams more than dry areas, the meter can differentiate between different reading.

Microwave dampness meters are the least known in the UK although they are finding their way into the professional standards of more and more European countries. They offer some major benefits in comparison to other meter types, being:

- Most accurate

- Deepest penetration: some meters can detect moisture up to 800 mm depth

- Most reliable: being impervious to ground salts, they only react to moisture

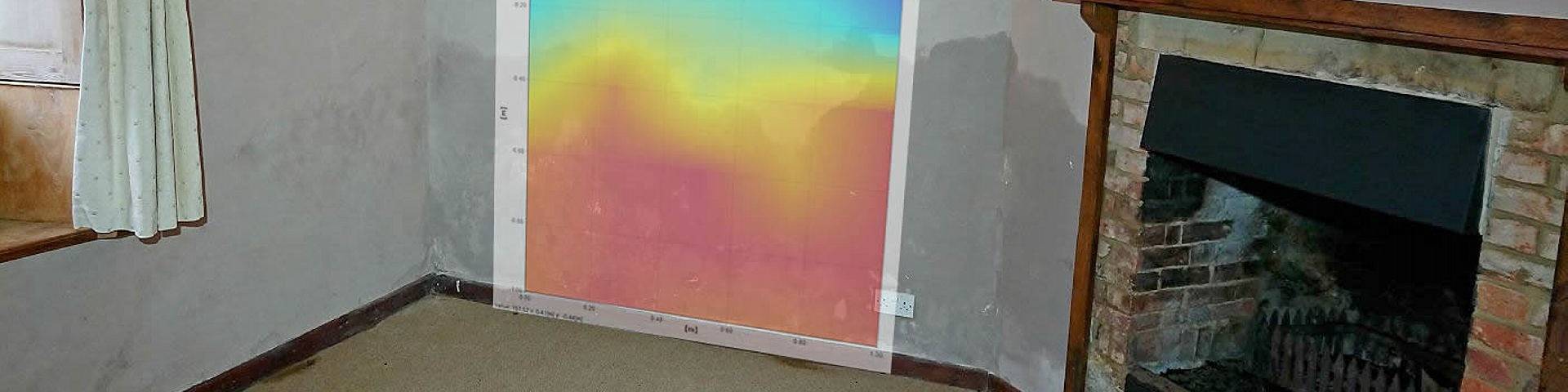

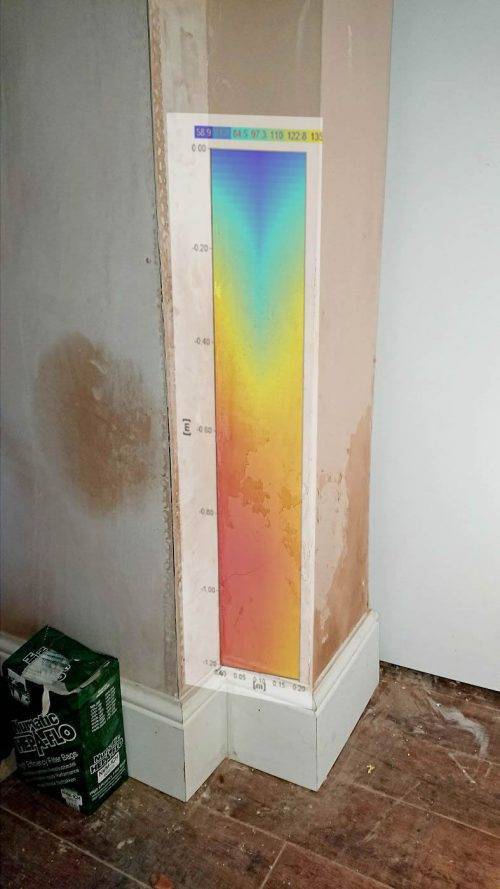

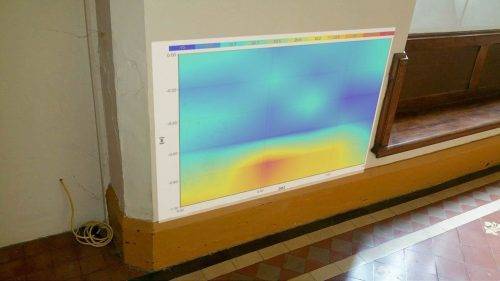

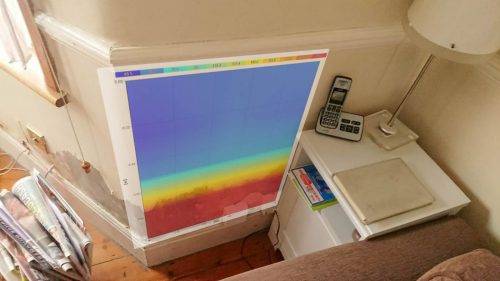

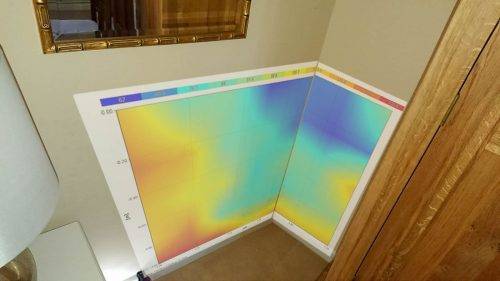

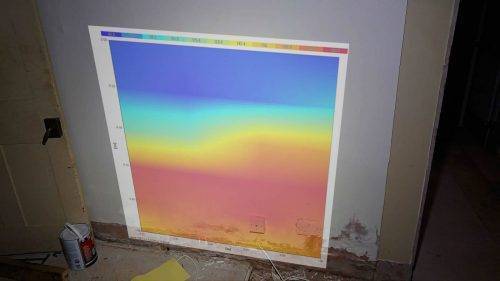

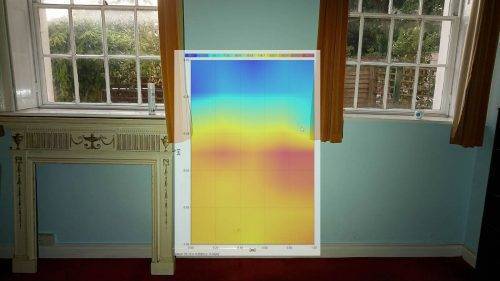

The downside is their high cost. Depending on configuration, accessories and software they can cost well over £1,000 so only professionals can justify the cost. Bundled software solutions permit further in-depth analysis of the wall fabric including the creation of moisture distribution charts to visualize the moisture content of the fabric at various depths.

Here are some samples images of the in-depth analysis microwave moisture meters make possible.

Limitations

It is important to understand that each dampness meter technology has its limitations. Although they can be great tools that allow professionals to "see" beyond the surface, they should be used in conjunction with other observations and measurements.

The practical experience of the surveyor is also important; an experienced one can much quicker can correlate the various data obtained from various sources, to come up with a rock solid diagnosis.

3. Drilled-Core Analysis (Gravimetric Analysis)

Drilled Core Analysis

Drilled-core analysis, also known as gravimetric analysis (gravi-metric = weight-based measurement) is the most accurate filed-based moisture measurement method, which is considered the "golden standard" worldwide.

This is what English Heritage says about gravimetric analysis in their conservation handbook Practical Building Conservation: Mortars, Renders and Plasters, which is used as reference guide by many conservation specialists throughout the country.

“Gravimetric analysis of a drilled sample is the most accurate of the analytical methods, and it is therefore used for calibrating other forms of measurements.”

– English Heritage

The moisture content of the masonry is determined from drilled powder samples taken from the depth of the wall using a small masonry drill, a precision scale and drying oven. Each wall sample is first weighted (wet weight), dried, then weighted again (dry weight). The weight loss is the evaporated moisture content of the masonry explained in percentages.

Gravimetric measurements, although very accurate, require dedicated instrumentation (gravimetric scale) which costs anywhere between £1,500 - £3,000. We have invested in several of these scales, all of our surveyors and engineers having their own equipment, being able to do accurate moisture tests and diagnosis on the spot.

Gravimetric analysis is an improved, more accurate version of the old calcium carbide test.

4. Professional Salt Analysis

Salt Content Analysis

Ground salts are the main cause behind the structural deterioration of masonry. Some salts can be natively found in bricks as they are made of clay. However most salts get deposited over time into the building fabric through rising damp or various environmental factors. Salts can either crystallize on the surface (efflorescence) as a white powdery substance or under the surface (subflorescence).

Determining the type and concentration of salts deposited in the wall fabric carries important information about the history of the building, the origin of moisture, and it is important when determining the best renovation process.

We perform the chemical analysis of the most important salt types:

- Chlorides: are sea salts. The most common sources of chlorides are sea-spray and salts from de-icing roads. They tend to stay soluble over 30% relative humidity. Buildings along the coast or close to the sea are typically affected by chlorides.

- Nitrites: the most common sources of nitrites are commercial fertilizers and manure. Being water soluble they tend to deposit in the upper part of the building; their concentration tends to increase with height and depth. Farm building, barn or stable conversions have typically very high amount of nitrates.

- Sulphates: sulphates are the most dangerous salts for porous materials due to their unique crystallization behaviour. They tend to crystallize on all surfaces regardless of pore size, and due to their longitudinal crystal growth they can exert a high enough pressure to crack the capillaries. Because they are less soluble, they tend to stay in the lower parts of the building.

5. Wall Cavity & Underfloor Inspections

Camera Inspections

Borescope or pinhole cameras can be very useful as they can provide valuable information from hard to access spaces. This can include the condition of the wall cavity, the composition and structure of the walls (e.g. in case of rubble infilled walls), the underfloor area for inspecting the condition of the floors and joists, or for tracing leaks and building defects.

6. Thermal Imaging (Infrared (IR) Thermography)

Thermal Imaging

Thermal imaging or infrared (IR) cameras have been used by quite some time for masonry diagnosis. Infrared cameras visualize changes in surface temperature and can be used to detect thermal bridges (areas of heat loss), leaks, moisture and water infiltration etc. Damp areas are generally cooler than dry areas and this temperature change can be picked up the thermal imaging camera and provide us additional information.

In addition to the measurements listed here we also perform other tests and measurements to solve specific situations.

Whatever your dampness problem is, we are likely to find its root cause which opens the road to resolution. We also like complex and challenging cases, so far we have solved them all. 🙂

If you have a dampness problem and need some help or guidance in diagnosing it, please get in touch, one of our friendly surveyors will get back to you.