Description

MASSETTO CALDO MGN (translates to "warm screed") is a filling and leveling screed that can be laid on timber, cement or brick-cement floors.

Composed of lime and cocciopesto (a traditional Italian brick or terracotta powder), it is particularly suitable for underfloor heating (radiant floors).

- It’s all natural, therefore healthy

- It is warm on its own in comparison to other floor types

- It is the ideal solution for radiant floors

- Much lighter than traditional screeds

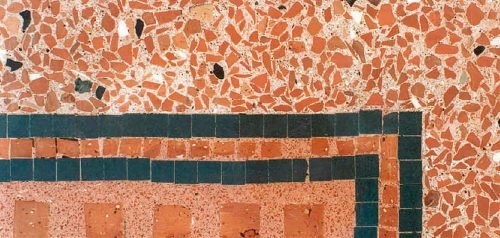

- It is the best base for prestigious Venetian or wooden floors

- Can be sanded/polished to restore its shine

- It is a faithful reproduction of the historical original

- Easy to spread even with a plastering machine

Once matured, it can be finished with timber, tiles or as a traditional Venetian floor. Here is a quick overview on how traditional roman or Venetian lime floors are made using traditional materials and techniques.

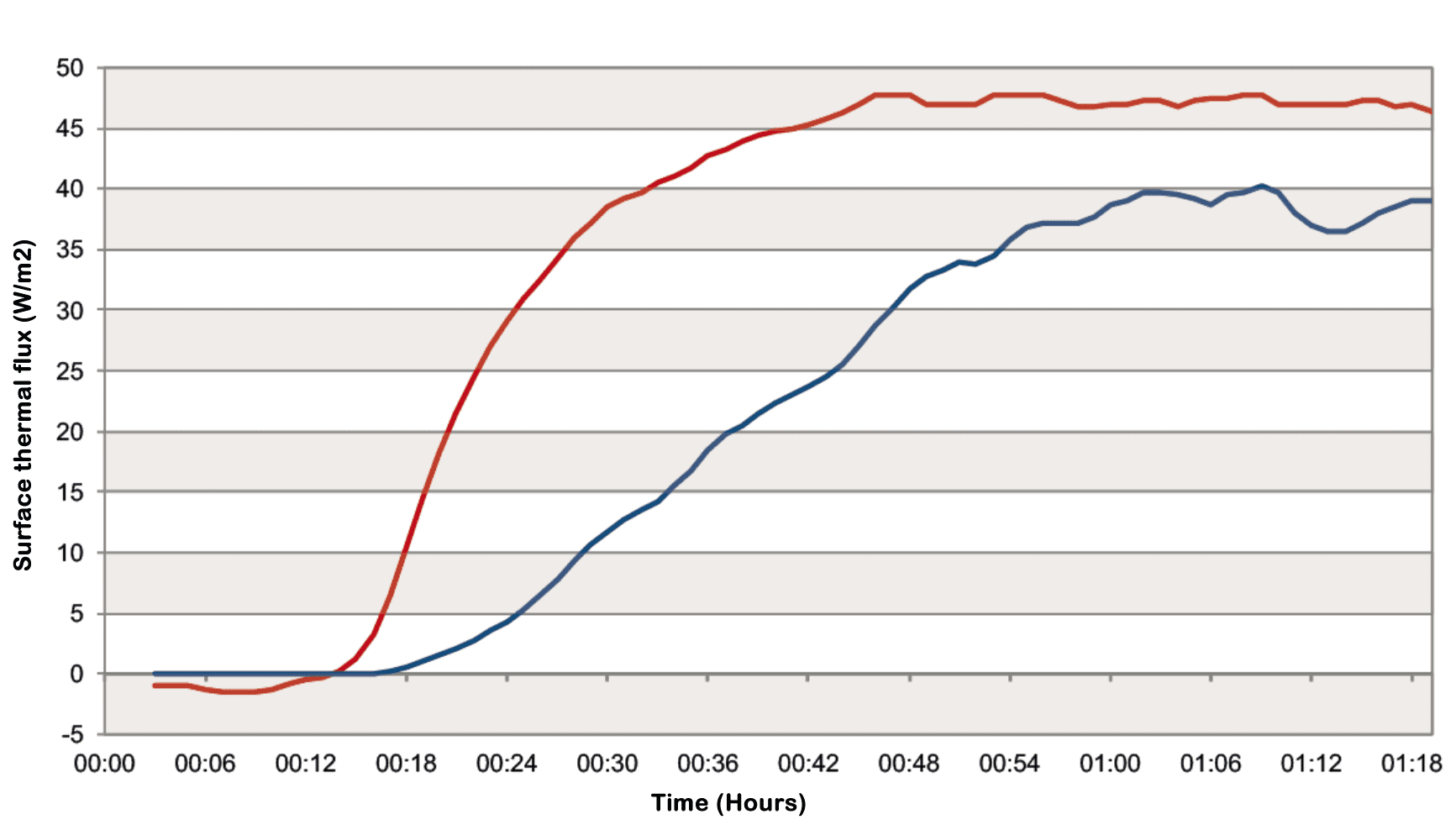

Performance - Comparative Tests

The Massetto Caldo MGN lime cocciopesto is not your typical contemporary screed. It is the result of years of research, experimentation and testing, both in the laboratory and on site, in order to reproduce and, if possible, improve the historic original.

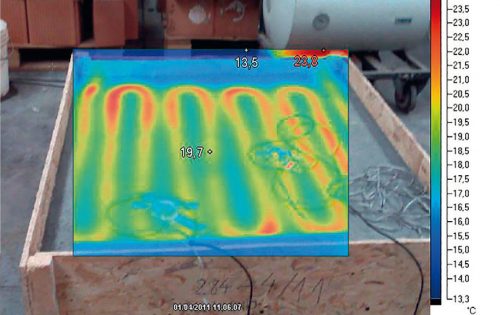

Tests were carried out at the CMR Laboratories in Italy to evaluate its performance in comparison to a traditional sand-cement floor. Specimens of lime-cocciopesto and cement screeds were prepared and applied to the same underfloor heating system, and surface heat flow measurements were undertaken on each.

Sample cement floor

Sample lime-cocciopesto floor

A 17 mm diameter hydraulic pipe circuit was fastened onto a 1000 x 1200 x 30 mm expanded polystyrene (EPS) panel. Above this the following floor samples were laid out:

- An everyday sand-cement screed, in 40 mm thickness above the pipes, with a specific weight of 1800-1900 kg/m3,

- A traditional cocciopesto MGN screed, in 40 mm thickness above the pipes.

Both floor samples were left to mature for 28 days, heating them artificially to accelerate drying, before taking any measurements. All samples were fed through a boiler capable of keeping the water circulating at a temperature of 32 °C.

Thermal flow measurements were carried via thermo-flow sensors placed onto the surface of the floors, in-between adjacent pipes of the hydraulic circuit. The sensors have been connected to an automatic data acquisition system, which was taking readings at a 1 minute interval.

Test Results

The above graph compares the surface heat flow generated by the two different floors. We can see how the cocciopesto floor has a steeper curve than the concrete floor. Moreover, it steadily outputs by about 16% more heat than a similar concrete floor.

This indicates that a cocciopesto screed heats up the living space faster and maintains it at a lower temperature of the water than a comparable cement floor.

Typical Applications

Floor base - for timber, tiled or traditional Venetian finishes

Technical Data

Here is some key technical data. Please see technical sheet below for more information.

Granular size | 0 - 5 mm |

pH | 12 |

Vapour diffusion resistance (μ) | 7.3 |

Thermal conductivity (λ) | 0.53 |

Compressive strength (N / m²) | 4.7 |

Adhesion (N / m²) | 0.4 |

Weight (kg / m³) | 1470 |

Consumption (kg / m² area / cm thickness) | 17 |

Bag weight (kg) | 25 (48 bags per pallet) |

Water intake (l / bag) | 4.5 - 5.5 |

Composition

- Hydrated lime, with more than 90% calcium hydroxide (CL90S as per EN459-1 standard)

- NHL3.5 Natural hydraulic lime, desalinated white

- Traditional cocciopesto (grounded brick powder, granulation 0-3 mm, cooked at low temperatures)

Colour

Light red (brick)

Downloads

Massetto Caldo Fine MGN - Italian technical sheet

English technical sheet will be available shortly.