Breathability

Breathability refers to a material’s ability to allow moisture to evaporate. If a material is breathable or vapour permeable, it allows the passage of water vapours through its pores.

The main mechanism how a masonry dries out is evaporation. A breathable wall fabric allows moisture to naturally evaporate out of the fabric and dissipate in the environment.

The vast majority of older building materials used before the 1850s-1880s are all breathable. Some examples of breathable building materials are clay bricks, lime plasters and renders, traditional paints, timber etc.

The Industrial Revolution around the 1850s started a shift in the building industry. With the development and introduction of newer materials, particularly with the discovery of modern Portland cement, many traditional breathable materials have been gradually replaced with non-breathable equivalents.

Most modern building materials used today – cement plasters and renders, plastic membranes, foams, modern petrol-based paints etc. – are non-breathable and as such they contribute to the accumulation of moisture inside the older building fabric.

Applying modern non-breathable materials to older buildings can cause ongoing and often hidden or stubborn dampness problems or make existing dampness problems significantly worse.

The video below summarizes the key concepts, otherwise keep reading. 🙂

Two Types of Moisture Barriers

While researching how water vapours interact with capillary surfaces, an important discovery has been made: a completely breathable wall fabric with no moisture barriers not only retains moisture which can build up to substantial levels.

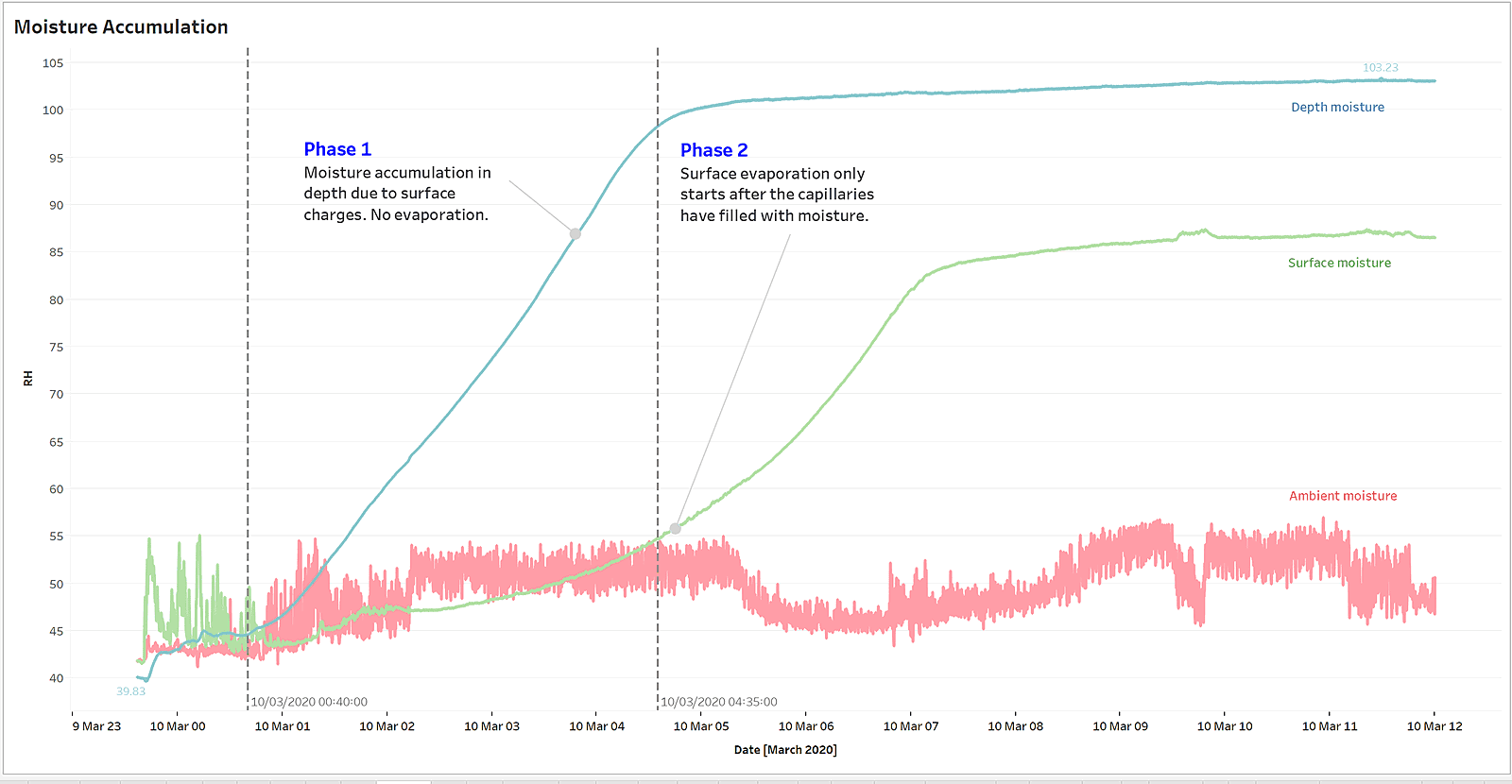

Moisture accumulates in a perfectly breathable masonry

When looking at how moisture accumulation starts in a completely dry wall fabric, there is a period when the humidity inside the wall fabric increases (blue line) but the surface evaporation (green line) is not present. During this time the masonry is accumulating moisture. Once the internal humidity nin the capillaries reaches 100% RH (blue line peaks), the excess moisture "overflows" and it starts evaporating out (green line increase).

This initially seemed like an anomaly, however further research has identified two important factors that determine the breathability of the wall fabric. These are:

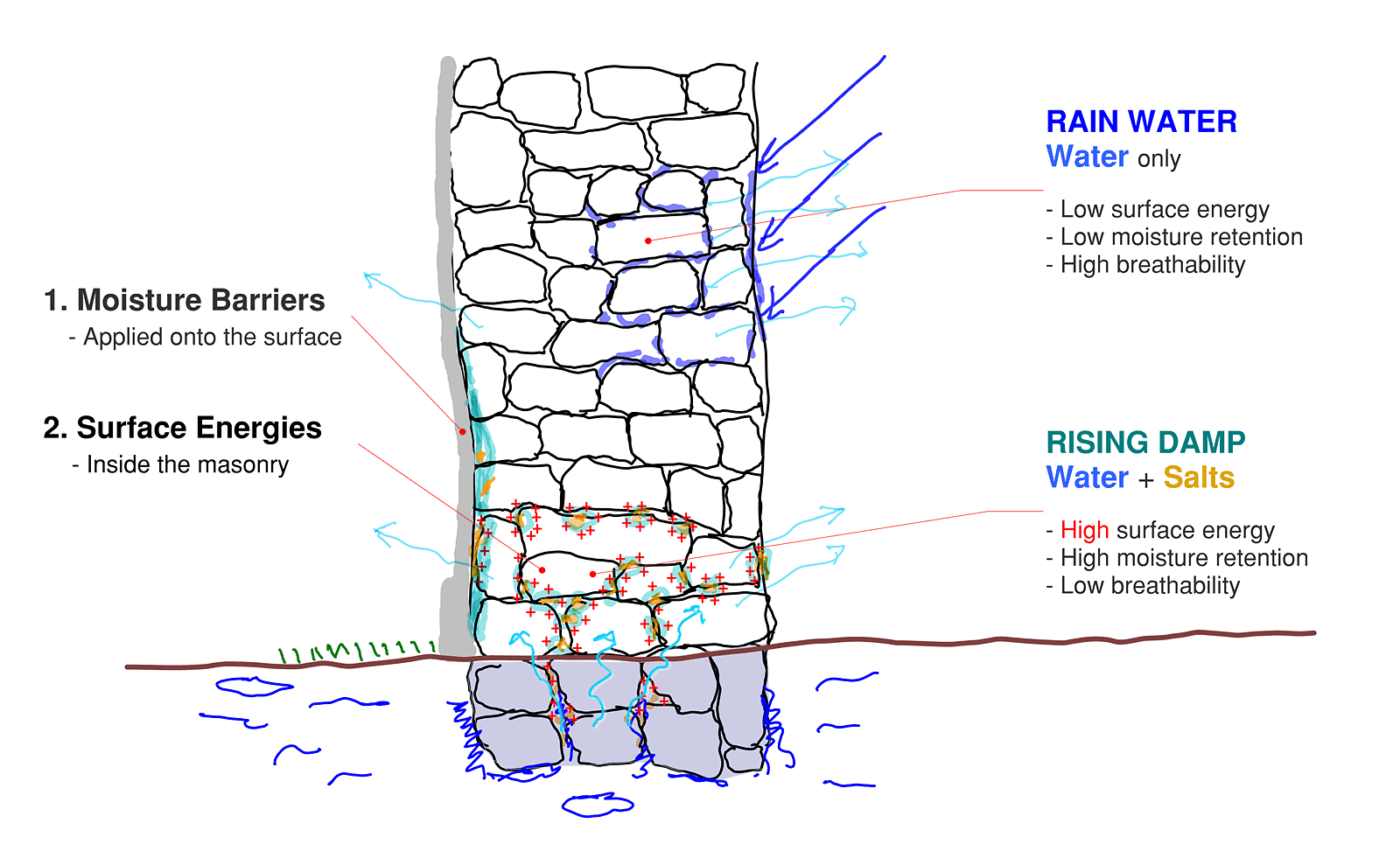

- Physical moisture barriers (presence or lack of it): certain non-breathable material hinder evaporation (e.g. cementitious plasters, plastic membranes, non-breathable paints etc.)

- Energy moisture barriers (surface energies): a less known fact is that the movement of moisture can also be blocked by various forms of energies, these acting as invisible moisture barriers.

Main factors affecting breathability

1. Physical Moisture Barriers

Physical moisture barriers are externally added materials or coatings which interfere with the free movement of moisture. Most common such materials are cement, plastic membranes and foams. Physical barriers hinder evaporation and thus make a wall fabric less breathable.

It is important to understand that breathability is a fine gradient scale with many values rather than a yes-no proposition.

The degree of breathability of various materials is measured by the vapour diffusion resistance (μ), the lower this number the more breathable the material.

Solid moisture barriers (e.g. cement) prevent evaporation, leading to moisture accumulation in the wall fabric

2. Energy Moisture Barriers

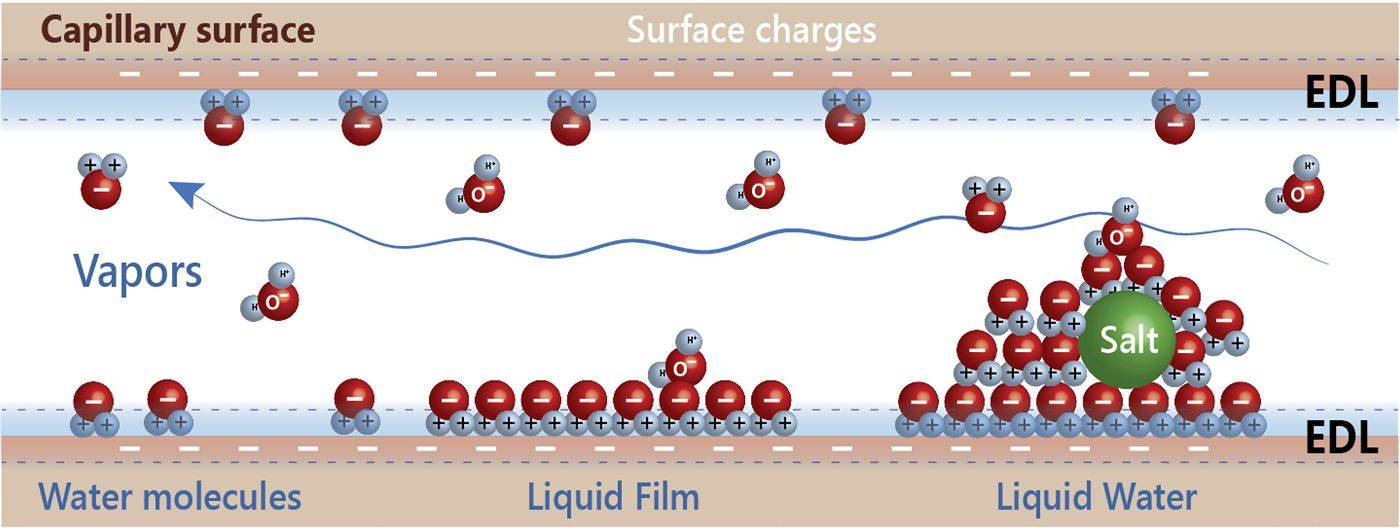

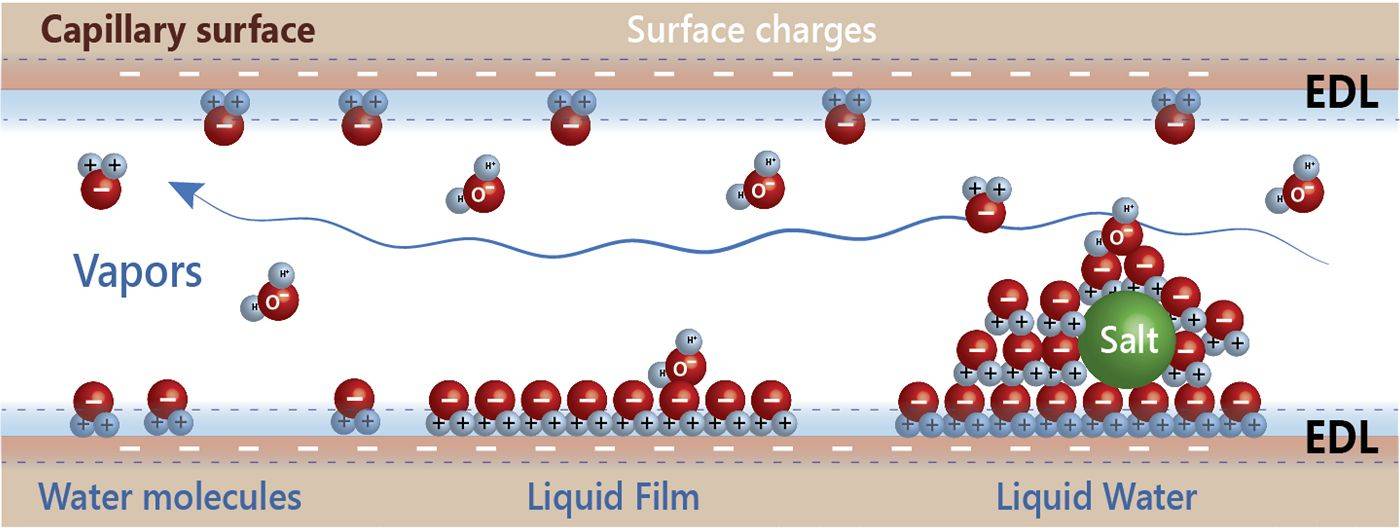

While the moisture-related damages of moisture barriers are well know, the fact that various forms of energy can also hinder the evaporation of moisture, are known to a less extent. The surface of all solid materials contain small amounts of static electricity - known as surface energy or surface charges or adhesion forces - which are strong enough to attract and bond the tiny water molecules to capillary surfaces, resulting in some moisture accumulation.

Surface energy traps water molecules, being a barrier to evaporation

The surface energy of materials is not a fixed value, permanently set in stone, but a variable thing that can be altered - increased or decreased - by multiple mechanisms, by physical, chemical or electromagnetic means.

Charged salt ions can significantly increase the surface energy of capillaries, creating higher charged surfaces by chemical or electro-chemical means. Various environmental conditions (e.g. storm clouds moving in, carrying a lot of electrical charges) can also affect the surface energy of masonry - in this case by electrostatic or electromagnetic means.

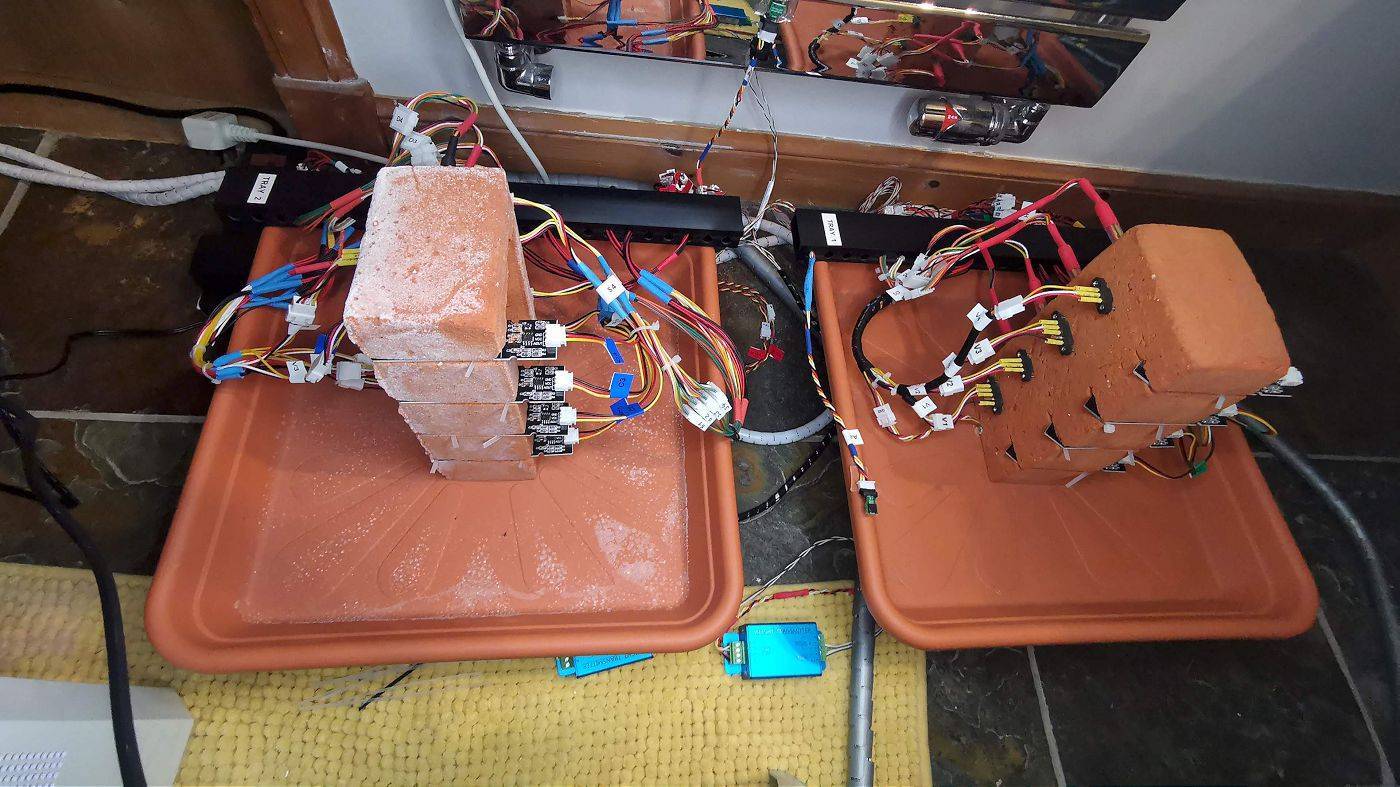

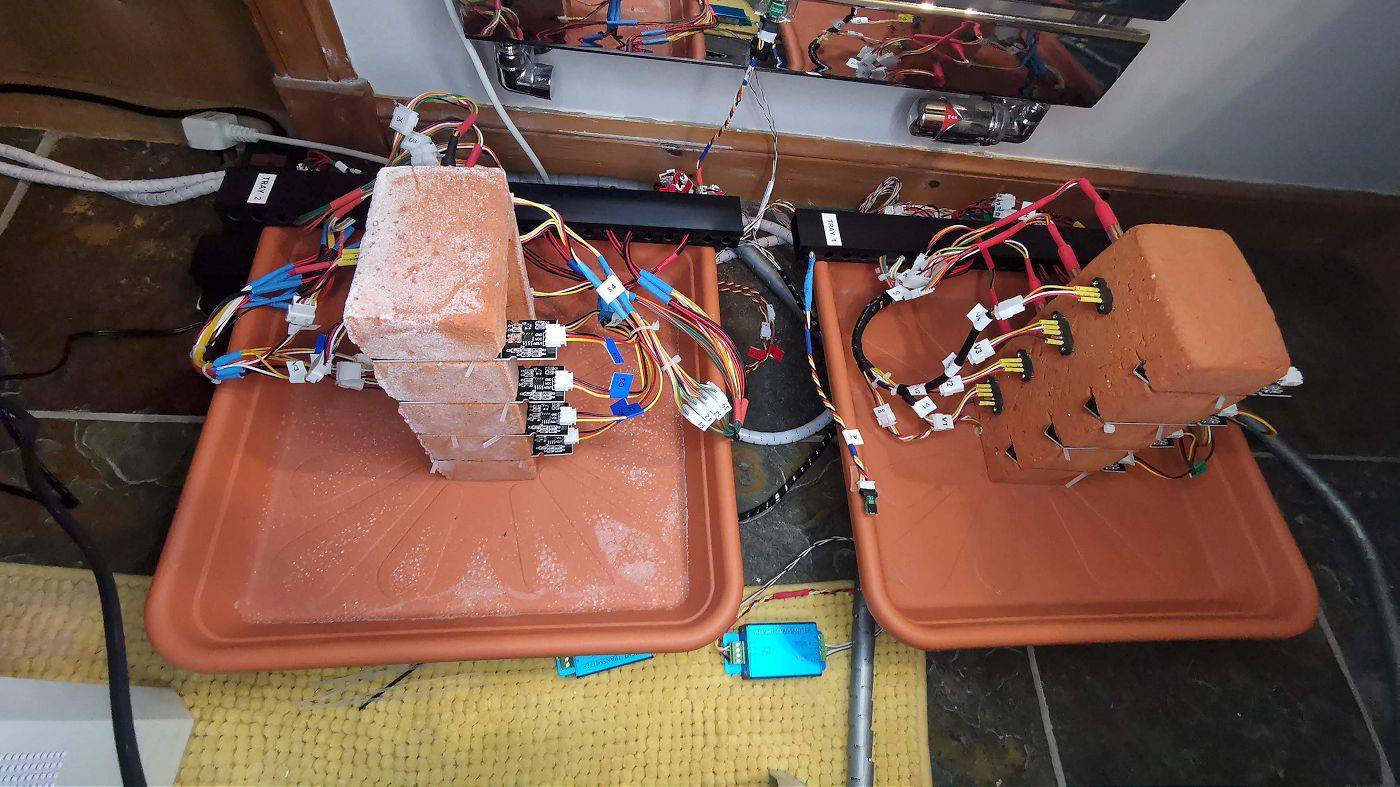

These surface charges can be measured in the masonry with a multimeter and expressed as a voltage. Here are some comparative measurements between two identical bricks - one salty, the other one not - under the exact same wetting/drying conditions.

Experimental setup - breathability of salty vs non-salty fabrics

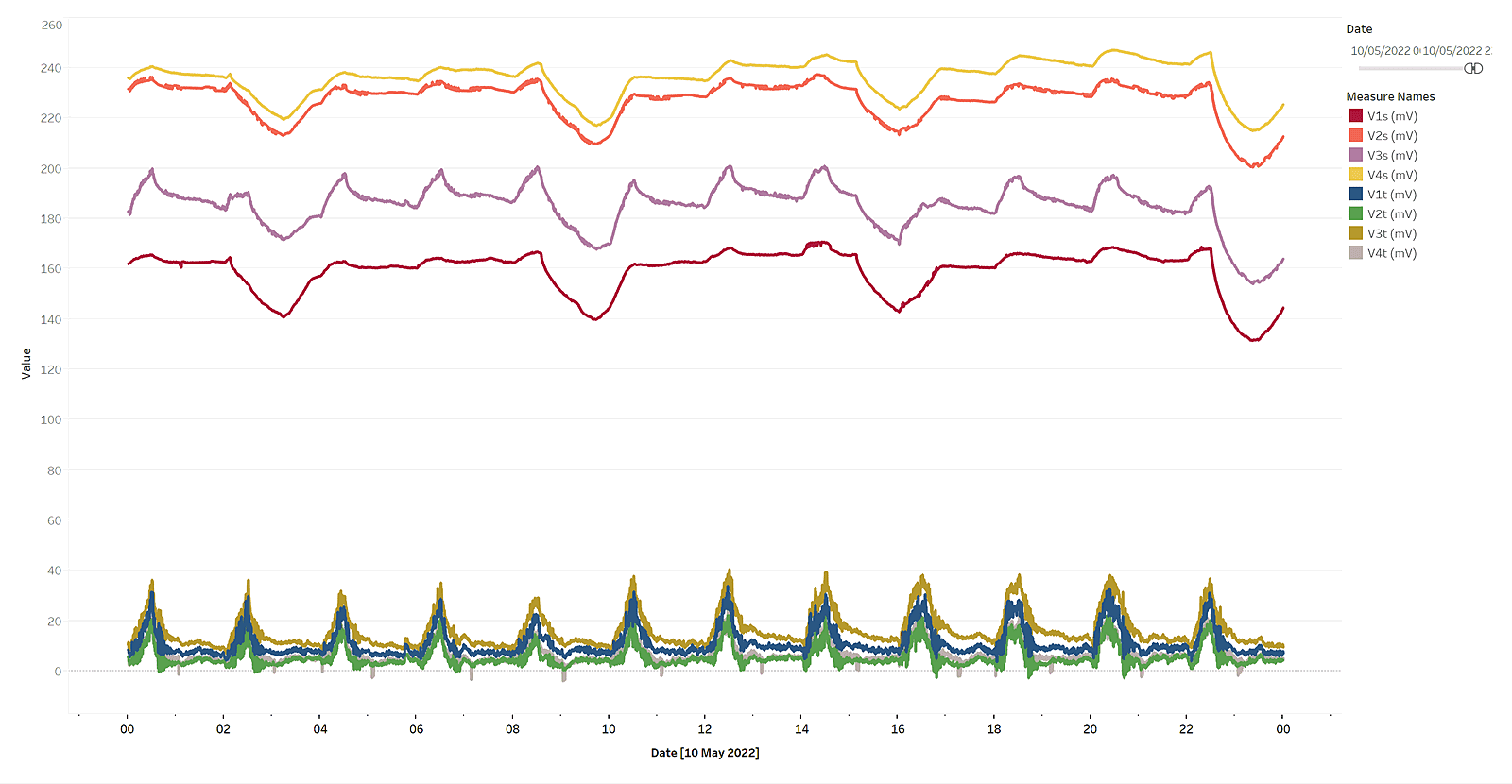

We can observe that the surface energy of non-salty brick is low, varying between 0 - 40 mV (green-blue lines), depending on the brick's moisture content. The similar salty brick has a much higher surface energy, which varies between 150 - 250 mV (red-purple lines), being about 4-6 times higher than the energy of the non-salty brick.

Charges in non-salty vs salty masonry

Why are these surface energies important? Because surfaces with higher energy can attract and trap more water than lower-energy surfaces, resulting in increased moisture retention and wetting, reduced evaporation and decreased breathability of the fabric.

Due to the electrical charges they carry, salts trap moisture and act as energy barriers, hindering evaporation while also decreasing breathability. The whole concept of hygroscopy - salts' ability to bond and hold moisture from the environment - can be explained with and occurs due to surface energies.

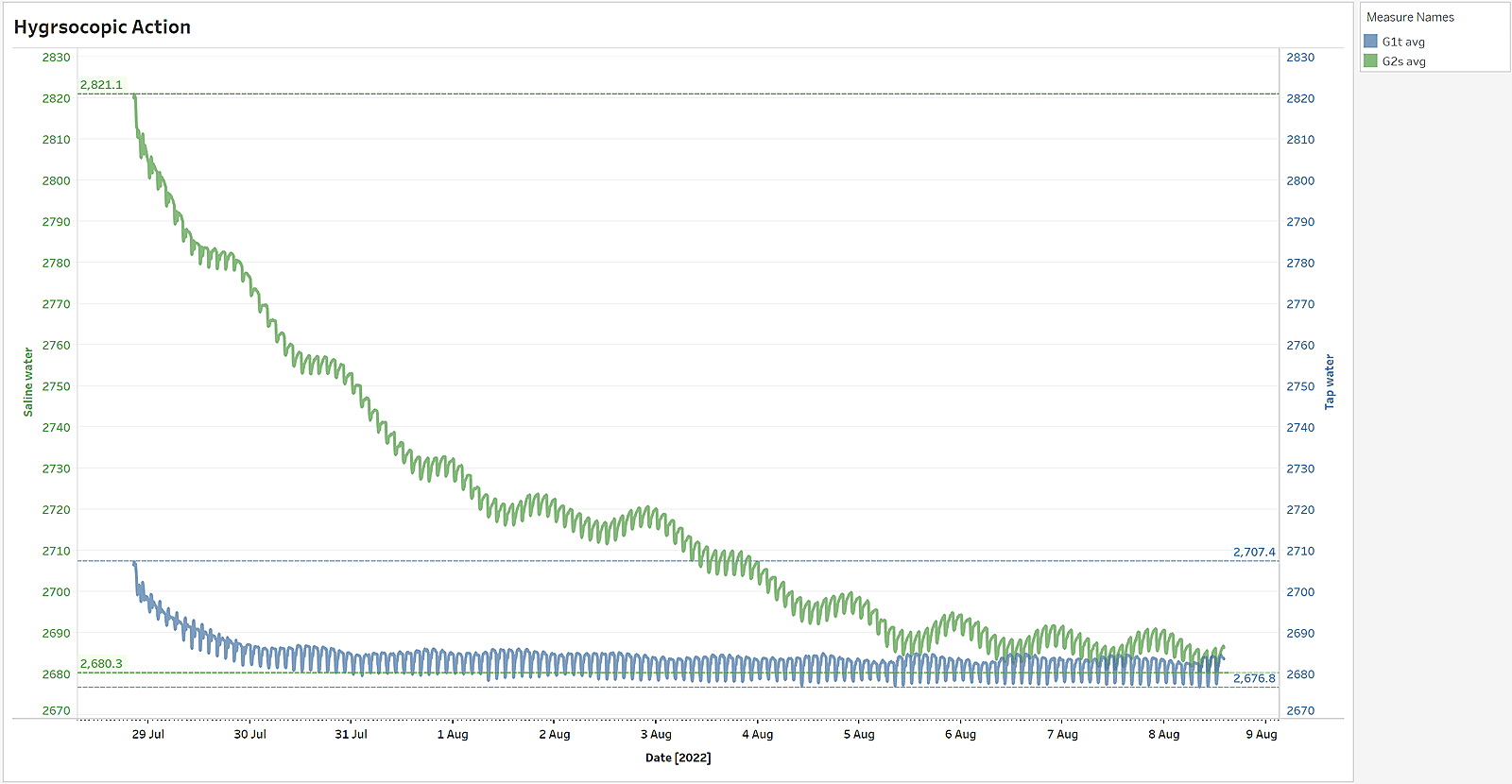

The graph below demonstrates this concept. The moisture retained by a salty brick (green) in a humid environment was 141 grams vs 33 grams of moisture retained by the non-salty brick (blue) - salty surfaces retaining about 4 times more moisture than non-salty ones. Moreover, salty, highly charged surfaces also let go of the moisture much slower, the salty fabric (green) drying out 7 times slower than the non-salty brick (blue) - a significant difference.

Salty surfaces retain a lot more water than non-salty ones

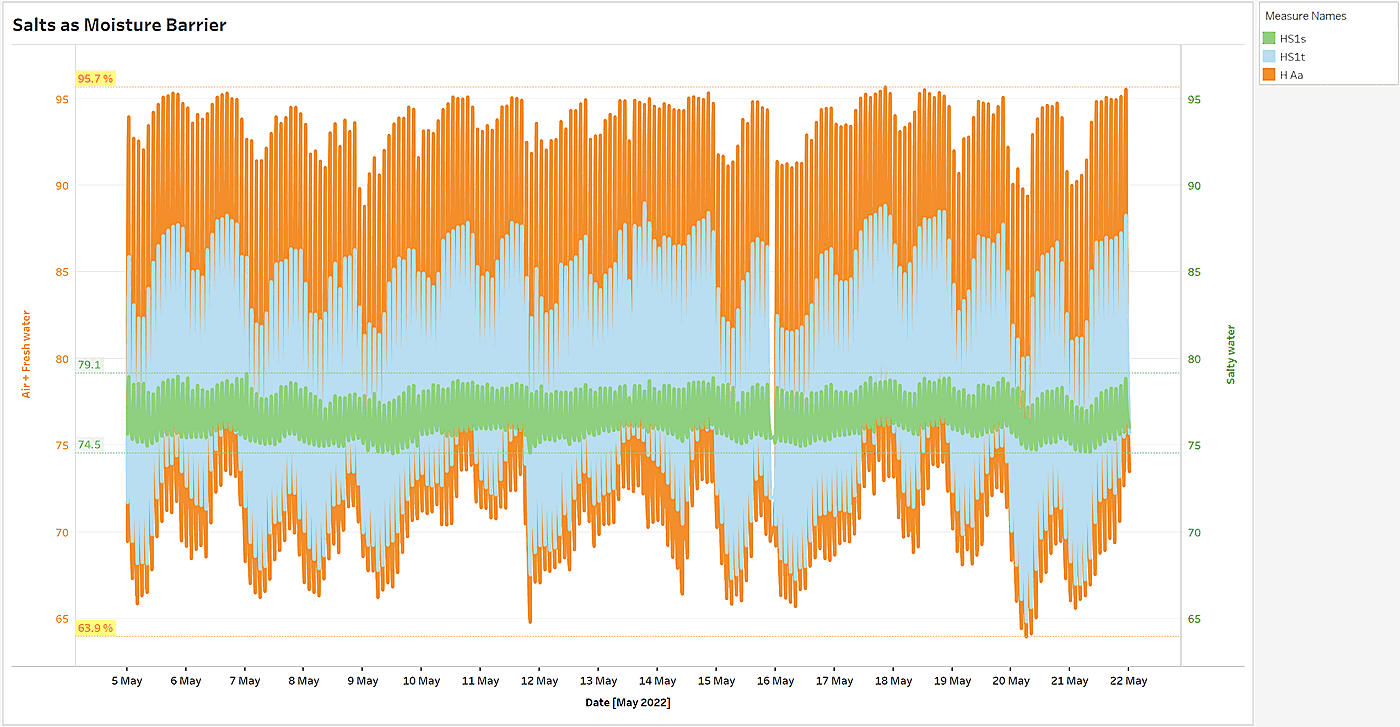

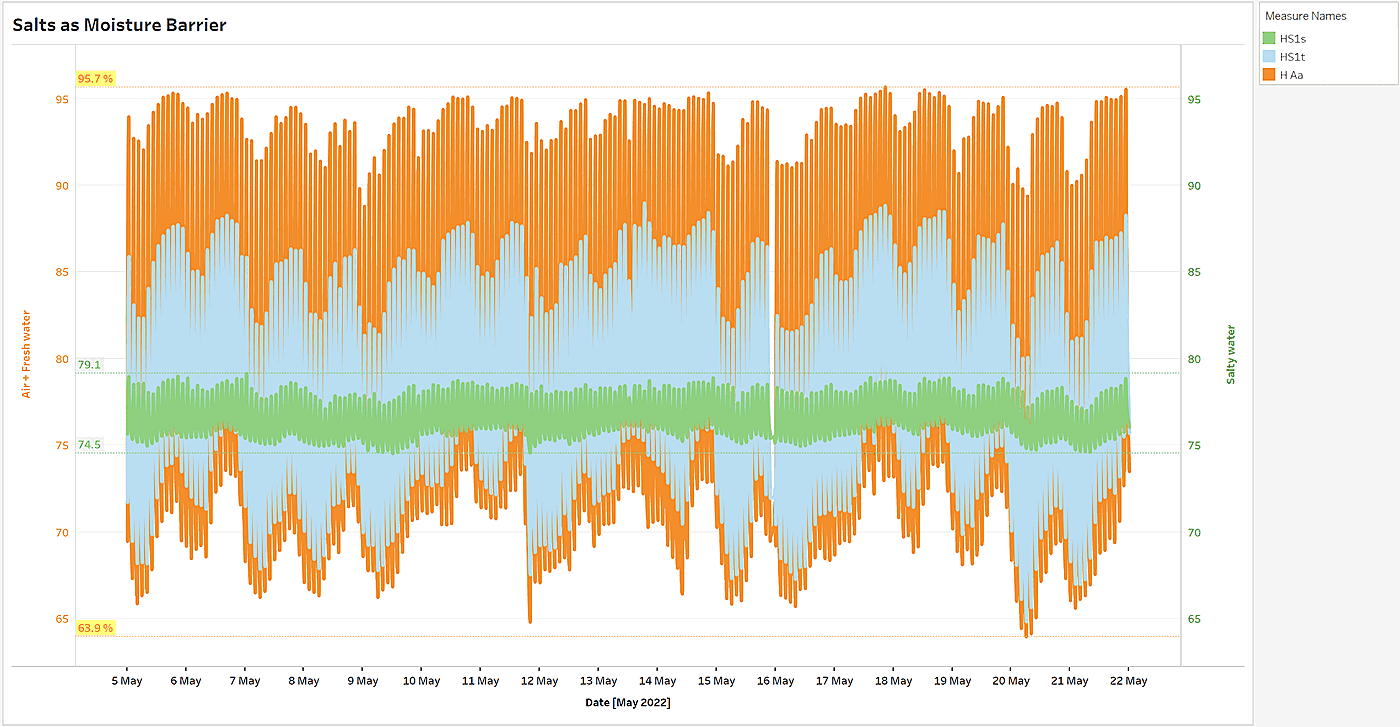

Here is another graph comparing the long-term retention of moisture by different surfaces, affecting breathability:

Water's ability to evaporate from salty and non-salty surfaces

- Free vapours in the air (orange band): have complete freedom of movement and most mobility. During successive wetting-drying cycles the moisture content of in the air varied between 63-95%, a 32% change.

- Evaporation from non-salty surfaces (blue band): the presence of some surface energies from non-salty wall surfaces reduced the evaporation of moisture by about 25% (in 65-89% range).

- Evaporation from salty surfaces (green band): the presence of additional charges or surface energies introduced by the salts reduced the evaporation of vapours by another 5 times in comparison to non-salty surfaces (from 25% to 4.6%, blue band vs green band).

Drying Out the Wall Fabric

Breathability directly affects a masonry's ability to release moisture and to dry out. Both non-breathable materials and surface energies affect the rate of evaporation and the drying rate of the wall fabric.

These findings explain why a wall fabric can dry out relatively easily after rain (intermittent wetting with little/no salts involved), and not dry out or just partially dry out when a significant amount of salts is present in the masonry – such as in case of farm or barn conversions, old churches and chapels, rising damp situation, around old chimney breasts, buildings close to the sea etc.

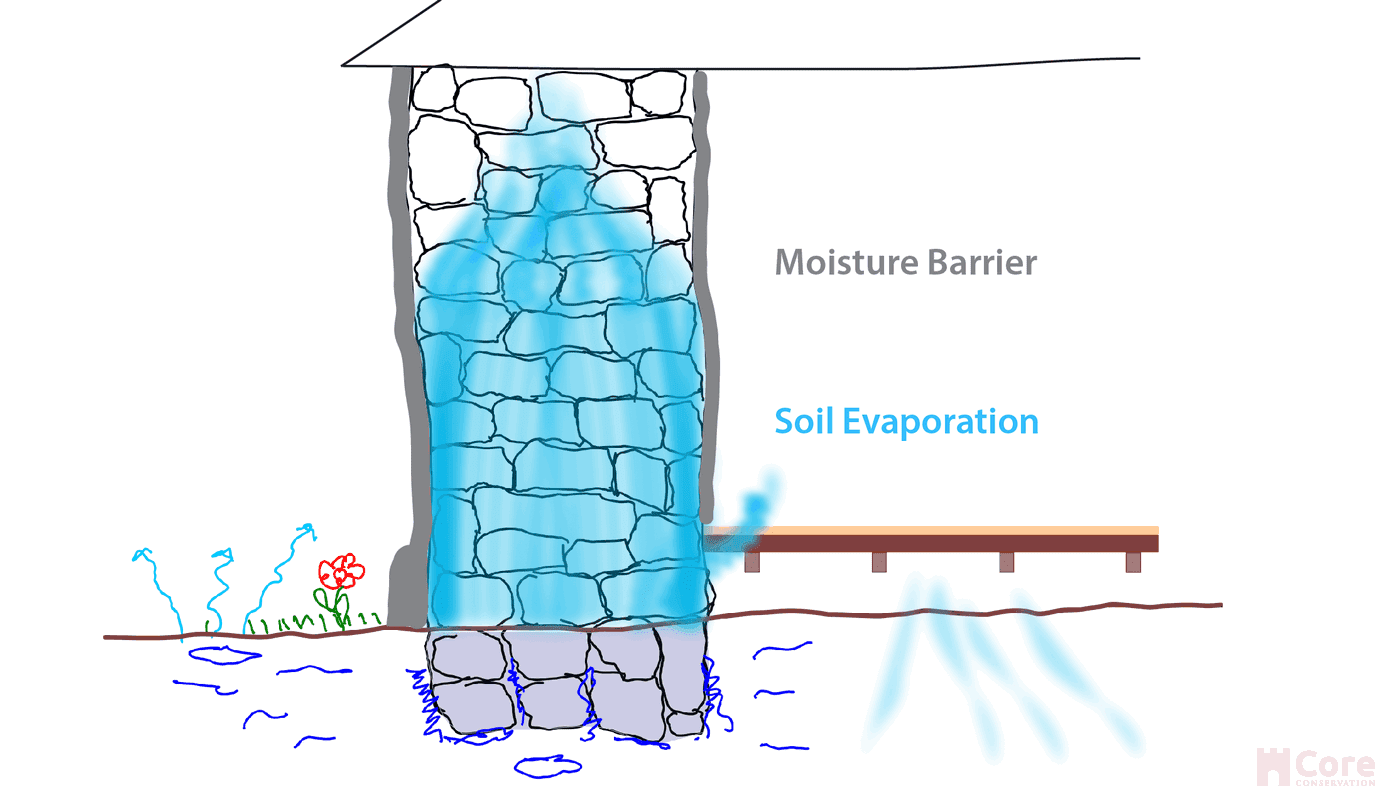

The presence of any physical moisture barriers (non-breathable materials) is bad for an old masonry designed to breathe because:

- It speeds-up the accumulation of moisture under the moisture barrier, making dampness problems more severe

- The increased moisture flow spreads the salts faster in the masonry, resulting in increased long-term decay

Thus, the removal of non-breathable materials is important step, as this increases the evaporation rate allowing the wall fabric to become drier. This, in many instances, brings about a significant improvement especially in not too old buildings with low-to-moderate salinity cases. In high salinity cases, however, one might only experience partial results: the surface might dry out, but under the surface the fabric remains mostly damp.

How much moisture can accumulate inside the fabric under breathable and non-breathable finishes? The video below demonstrates the concept.

It is also important to understand that physical moisture barriers are never the primary cause of dampness problems. Moisture barriers just make some pre-existing dampness problem – often a hidden one – worse, by making moisture accumulate.

Without an underlying moisture source dampness can’t accumulate. The reason why no one is concerned about the breathability of newer buildings is because the fabric is dry, so there's no need to evaporate out anything.

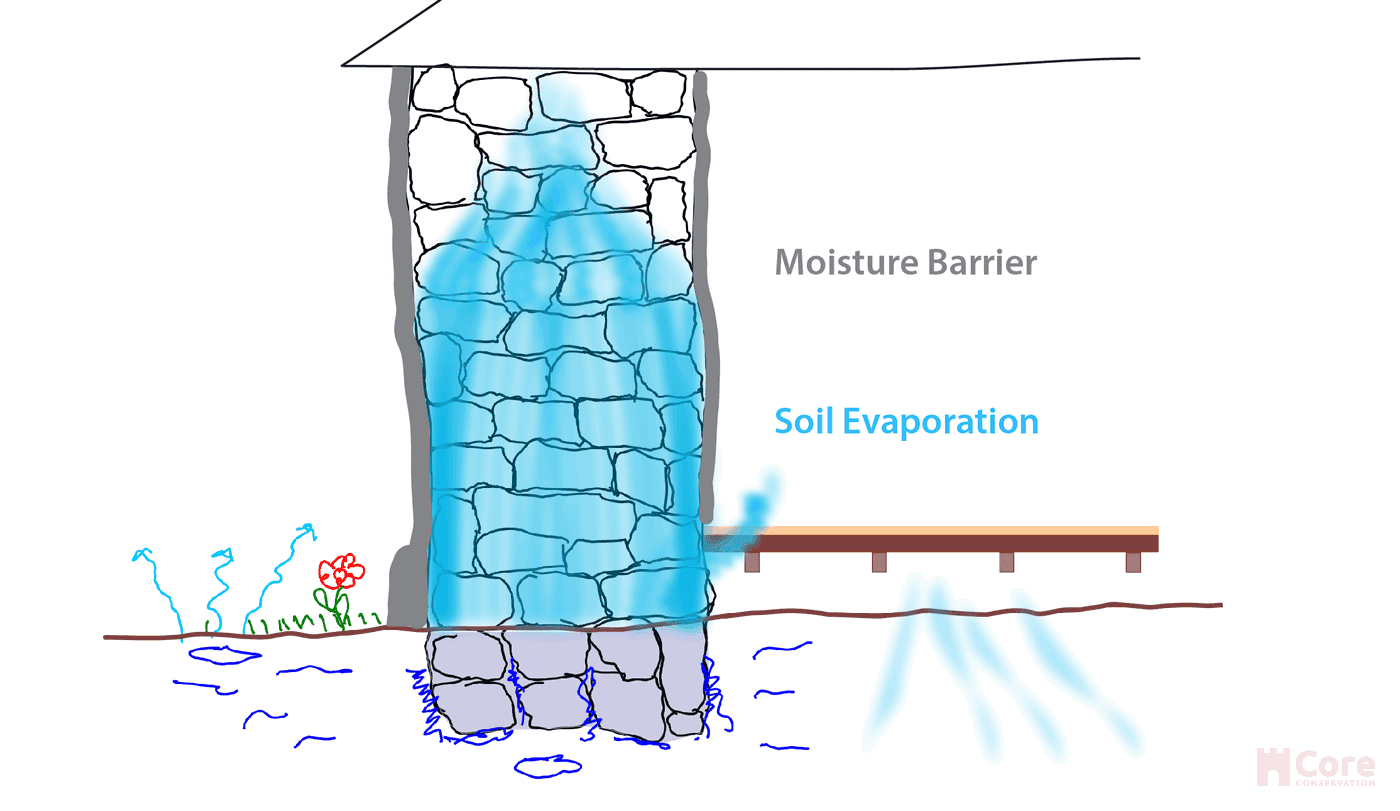

A common hidden moisture source in old buildings is the evaporation of soil moisture from under the building, causing rising damp. Non-breathable plasters trap this moisture making it to accumulate and liquefy inside the wall fabric. The increased moisture content dissolves and spreads the salts further, leading to ongoing plaster damages. Replastering temporarily improves the problem, but if the underlying moisture source is not solved, the plaster damages will appear again after some time.

These and many other aspects related to rising damp are discussed in detail in the rising damp section.

To further reduce the moisture content of the masonry, especially when salts are also present, decreasing the surface energy of the fabric offers another alternative, complementing the removal of moisture barriers. The magnetic DPC technology does exactly that.

Summary

There is more to breathability than just removing non-breathable materials, which is only half of the story. The other half is the surface energy of the masonry, the degree of breathability of a wall fabric being determined by both of these factors.

Salts are energy barriers which can reduce evaporation and the breathability of the fabric significantly. limiting the benefits provided by the removal of physical moisture barriers.