In the previous section we covered a brief history of plasters, highlighting the various types of plasters and how plasters have evolved and changed over time.

Let's see now the main type of plasters, how they compare and what factors determine their most important properties.

Main Plaster Types Today

As mentioned earlier, older and newer buildings are built very differently: different materials, different building philosophy, different ways of dealing with moisture.

In a nutshell: older buildings have been designed and built to be water permeable. Being built from breathable materials, they allow for a large percentage of the moisture to freely evaporate. On the other hand, newer buildings are built to be watertight using many modern materials designed to keep moisture entirely out.

This highlights a major shift in building philosophy that occurred somewhere during the Industrial Revolution (from the early 1800s onward). While plasters used during the antiquity, middle ages and Renaissance period were predominantly lime-based, during the Industrial Revolution a gradual but marked shift occurred in the direction of harder, faster-setting cement-based plasters and materials.

Today a wide variety of plasters are available on the marketplace, catering to both older and newer buildings, with very different characteristics. The most important types of plaster are the following:

Cement Plasters

Most plasters available today commercially are cement-based plasters. They are mainstream in the building industry. During the past 100 or so years they have taken over the building industry and gradually replaced traditional lime plasters almost completely.

Some of the reasons that lead to this state of affairs was:

- Industrialization: the need to erect many buildings quickly. Cement plasters set much quicker than traditional lime plasters allowing faster building.

- Novelty: in the Industrial Era cement, the new building material, was regarded by many as better, more performant material in comparison to existing lime plasters.

- Lack of research about their long-term performance: lack of long-term data about the aging and longevity of cement as well as some of its undesirable characteristics also fueled the hype that it is a better material.

Gypsum Plasters

Gypsum plasters are mainly used as decorative finishes on top of cement plasters, Being very soft they have excellent workability resulting in silky smooth finishes. On the downside: being so soft, they easily break down in the presence of humidity and salts.

Lime Plasters

Lime plasters are the oldest type of plasters known to man. Their history goes back about 10,000 years predating the Romans and Egyptians. Lime has been extensively used throughout history and has a very rich heritage. Lime plasters are the right material for older buildings, practically any building built up to the 1930s.

Lime plasters can be manufactured from pure lime stone, resulting in very breathable lime plasters, but with low resilience to water and salts (hydrated or aerial limes). By using a less pure lime stone, which contains clay impurities, the water resistance of lime can be increased (natural hydraulic lime or NHL plasters).

The various types of plasters can often be recognized from their color and texture. Lime plasters tend to be white or yellow in color, depending on the type of sand used and often has larger granules of sand or smaller pebbles embedded into it. Cement plasters are mostly grey and tend to be smoother at touch. They are much harder than lime, scratching them with a key barely leaves a scratch mark on the surface. Gypsum plasters are light brown in color with a hint of pink, they are soft and very smooth.

Lime pointing

Cement pointing

Gypsum plaster

Here are some sample images of the most common plaster types from various projects we have done around the country.

Water Resistance vs Breathability

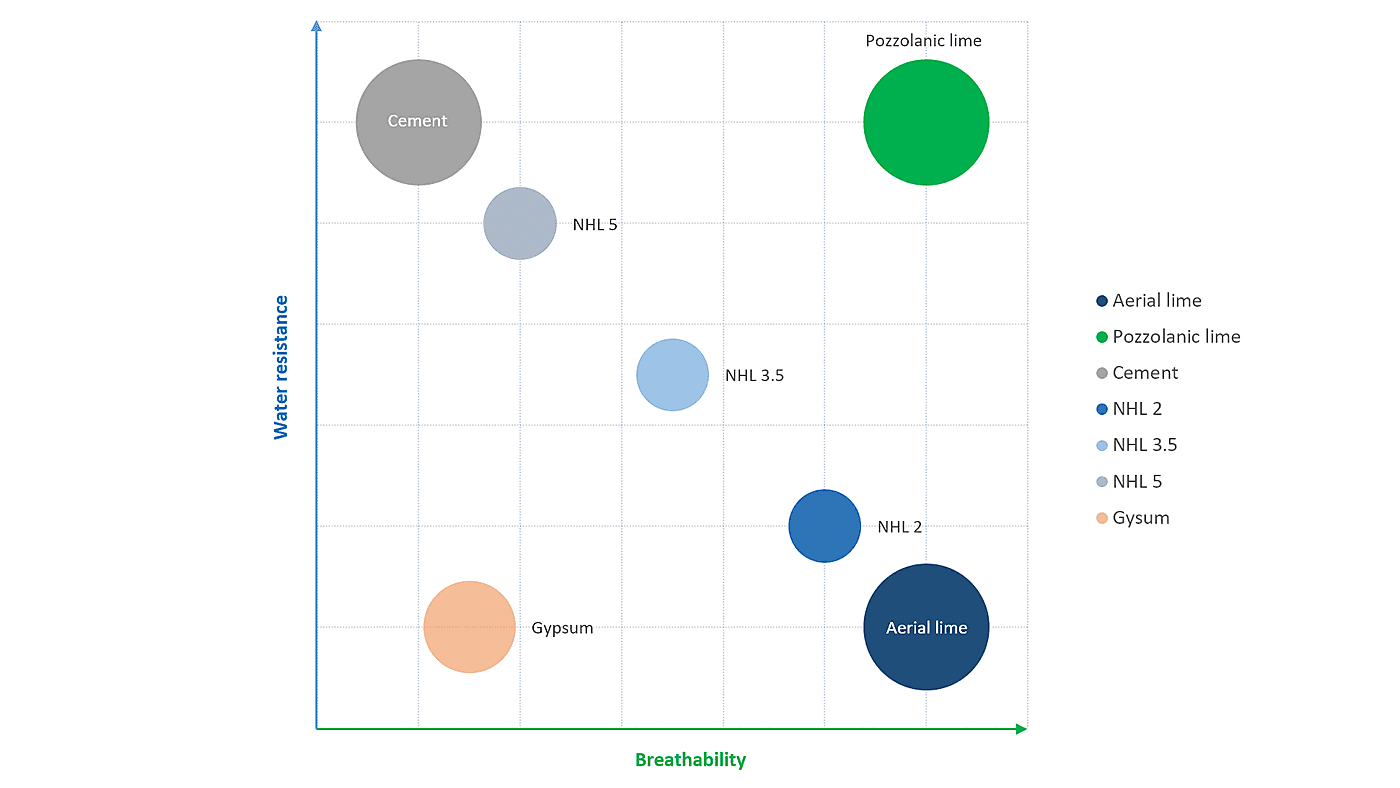

Modern plasters trade water resistance for breathabiity.

- On one end of the scale we have hydrated (aerial) lime plasters with maximum breathability and minimum water resistance.

- On the other end of the scale we have Portland cement with good water resistance but minimum breathability.

- In between the two we have the various strength NHL plasters trading water resistance for breathability, Increasing the amount of of impurities (clay content) results in stronger but less breathable NHL plasters.

Traditional Roman pozzolanic lime plasters (green) offer full breathability and water resistance in the same time, keeping the building breathable while lasting a long time in the presence of water and salts.

Water resistance vs breathability

Why Lime is Better for Old Buildings than Cement?

Most old building owners are aware of the fact that cement plasters on old buildings should be avoided and lime plasters should be used instead, The reason behind that is that lime and cement plasters, as building materials, have very different properties.

Here are the differences between traditional lime and modern cement plasters, and why lime is a better choice for old buildings than cement:

- SOFT: lime mortars are softer than cement. In fact, their hardness can be controlled during the manufacturing process. However if chosen correctly, lime must be softer than the bricks they bind together.

Imagine lime mortar as an air cushion on which bricks rest. Buildings are subject to constant ground movement and vibrations. A soft cushioning can accommodate this minute movement without cracking. Over the years the soft lime will erode but it will protect the surrounding bricks, keeping the historic building fabric intact for centuries.

Cement render on the other hand is rigid. It cracks badly, letting rainwater in, resulting in increased dampness and potential frost damage. Cement mortar being harder than surrounding bricks, will erode or crack them, damaging the softer historic building fabric. - BREATHABLE: on molecular level lime allows water vapours to evaporate freely, keeping its surface dry. Cement, on the other hand, prevents evaporation and traps humidity. Moisture under the cement plaster gradually builds up, "amplifying" dampness problems, making them worse. Cement around timber can lead to rot.

- WARM: lime having large air-filled pores, is a good thermal insulator, making it a cosy and warm material. Cement, being significantly denser with few pores, it is much colder which often leads to condensation and mould problems.

- ANTI-BACTERIAL: lime being alkaline, it has natural antibacterial properties. It is a natural mould killer. A natural way of disinfecting cellars in the past was to paint them with lime wash.

- ECO-FRIENDLY: lime is eco-friendly and carbon-neutral. After reaching its end-of-life it can be recycled: crushed and re-used for the next lot of lime mortar. Cement is not reusable but ends up in the landfills. It also has a heavy environmental impact: the cement industry produces 10% of global man-made CO2 emissions. Heavy metals are also commonly found in cement in non-negligible concentrations.

Why Is Cement Still Used on Old Buildings?

Despite many of its advantages, lime plasters are still used a lot less than cement plasters. This happens for several reasons:

- History: before the turn of the century (1900s) lime was the "golden standard" for thousands of years. Then cement has been invented. Being waterproof, fast curing, harder, capable of supporting larger loads etc. it quickly became the new "wonder material" allowing properties to be built on industrial scale: more, faster, taller - something which was more time consuming with lime. Thus lime has fallen out of fashion being largely "forgotten" for several decades. During this time the shortcomings of aging cement came to light - problems of durability, cracking. poor aging etc. - and after the 1980s the building industry started returning to lime. Today lime is living its second Renaissance, becoming increasingly popular again,

- Lack of knowledge / education: due to lime being largely forgotten in the 1970-80-90s, many builders and small traders just don't know or have never been taught about lime as an alternative. So they just use cement. According to customer feedback about 70% of the tradesman / builders out there do not work with lime, so we know at times it can be challenging to find the right tradesman for your old building project.

- Time considerations: lime cures slower than cement, it needs more time to dry. There is a 1-2 days wait period after each coat applied. Cement on the other hand sets within a few hours, making possible a faster turnaround between jobs. As "time is money", many builders choose to use cement because it's more cost effective to them; they can get more jobs done in less time.

Things are slowly changing though. More and more building owners as well as professionals are becoming aware of the real benefits of lime. Many heritage organizations and groups - such as The SPAB, English Heritage, The National Trust, The Listed Property Owners Club (LPOC), The Lime Centre etc. to name a few - are making a tremendous job in popularizing lime, a key ingredient in better preserving our old buildings for the future.