Description

One of our unique products is RINZAFFO MGN, a plaster developed in 1980 in Venice to the problem of capillary rising damp, penetrating damp and salts, however its origins stretch back to ancient Roman times.

It is a breathable salt resistant lime scratch coat, which protects subsequent plaster layers from the destructive effect of salts. Because it is both waterproof and breathable in the same time, it is suitable for a number of specialist applications such as:

- A base coat in any building subject to rising or penetrating damp

- A render against driving rain

- A plaster against the damp patches, discoloration or the crystallization of salts (sulphates) around old fireplaces and chimney stacks, a frequent problem in old buildings

- A lime-based "tanking slurry" to make basements or cellars waterproof

- As a waterproof (but breathable) floor screed to prevent flooding in high water-table or pressure water situations

- A plaster against splash water for rebuildings plinths

The RINZAFFO MGN system, due to its unique pore structure, prevents the crystallization of salts inside its pore structure. By regulating the evaporation of humidity it keeps salts residing inside the capillaries in a dissolved state thus prevents the rapid crystallization of salts often resulting in the detachment of plaster and deterioration of masonry.

With Rinzaffo MGN the surface of the plaster stays dry and healthy, and the appearance of the interior remains aesthetically pleasing.

The life expectancy of the plaster is very long even in "heavy-duty" damp and salty environments, if applied correctly, it can last over 40 years.

Application Examples

Here are the key points about the application of the plaster:

- Clean the masonry: the plaster must be applied on a cleaned and uniformly wet substrate. All crumbling and loose parts must be removed by brushing so the masonry is free of dust, salts and oils. If possible, also wash the walls with a pressure washer; this will clean and wet the walls in one go. Close larger holes with lime mortar and pieces of bricks.

- The Rinzaffo MGN plaster must be the first coat on any wall. It should not be applied on top of other plasters because when those fail the performance of the Roman base coat will also likely to be affected.

- Masonry paints should be removed (which occasionally can be challenging) so the plaster can firmly adhere to the underlying stones or bricks. Remove at least 50% of the existing paint – the more is removed, the better.

- Mixing: mix the material with clean tap water only without adding any other materials or additives, until a homogenous, creamy-consistency mix is obtained.

- Wet the wall fabric abundantly before applying the plaster, as well as between each coat. If the walls are already damp, there is no need to wait to become drier, you can proceed with the application of this plaster.

- Level uneven surface first: very uneven walls (e.g. stone walls or crumbling old brick walls) are recommended to be patched up and levelled first before the application of a continuous coat, to ensure the consistency and required thickness of the base coat.

- Recommended thickness: min 10 mm (1 coat) for freestanding (above ground level) walls. Min 20 mm thickness (in 2 coats) for underground or extremely salty wall sections. If more than one coat is applied, embedding a 10 x 10 mm fibreglass mesh is recommended between the coats – a standard practice in the industry.

- IMPORTANT: attention should be paid to compact the product on the substrate and close off all pores, no matter how small, not leaving any holes where salts or liquid moisture could resurface. Once the surface has been completed, check again that here are no missed holes, not even small ones.

- Application: apply the plaster in 10 mm coats.

- Additional coats can be applied in 10 mm increments. Use an embedded fibreglass mesh for extra reinforcement over the recommended thickness.

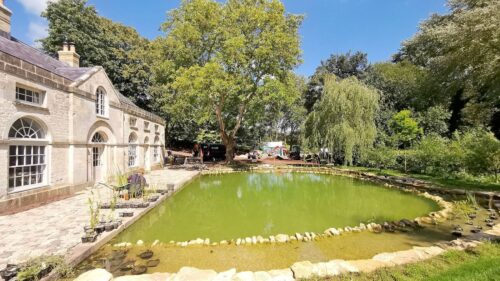

Here are some application examples of the Rinzaffo MGN salt-resistant lime plaster.

Click on any of the images to open the photo gallery.

Videos

Application of the Plaster

Here is tutorial about how to apply the Rinzaffo MGN plaster correctly, demonstrated by Mr. Naldo Busato - Venetian Building Restoration Master.

Most important points are summarized below:

- 00:00 - Start

- 00:04 - Introduction

- 00:37 - Mixing the plaster

- 01:06 - Preparing the wall surface

- 01:37 - Wetting the walls

- 02:39 - Leave no holes or gaps during application

- 03:19 - Compact the surface

- 03:33 - Do not overthin it

- 04:44 - Fibreglass mesh

- 05:12 - Give it a light key

- 05:38 - Dark spots indicate insufficient thickness

- 06:22 - Condensation while drying

- 07:40 - Plastering machine application

- 08:27 - Finishing near floor level

- 09:49 - Cutouts for sockets

- 10:26 - Wall anchors

- 10:53 - Summarizing the key points...

- 11:50 - Performance testing

Performance Testing

The Rinzaffo MGN mortar has been subject to a series of very demanding tests, both in the lab and on real buildings such as being constantly submerged in the high tides of Venice.

Here is a short summary on some of the tests performed:

- 00:36 Salts resistance test: resistant to all salts, including chlorites, nitrates, sulphates. Extensive history: 22 years of lab testing, nearly 40 years of field testing

- 02:00 Water resistance test: it's waterproof

- 02:47 Sideways pressure resistance

See the video below for more details on how well the plaster performs in very damp and saline environments.

Technical Data

Here are some key technical data. PDF Technical sheets can also be downloaded below.

Granulation | 0 - 3 mm |

Consumption (kg / m² / cm thickness) | 16 |

Fire rating | Class A1 (what this means) |

Weight (kg / m³) | 1,744 |

Vapour diffusion resistance (μ) | 15 |

Thermal conductivity (λ) | 0.96 |

Adhesion (N / m²) | 0.4 |

Water absorption | W0 |

Water intake (litre / bag) | 4.5 - 5.5 |

pH | 10.5 |

Bag weight (kg) | 25 |

Presence of harmful substances | Absent |

Composition

- Natural volcanic ashes and sands (natural pozzolans)

- NHL 3.5 Natural hydraulic lime

- Marble powder

- Washed sand, free of salts and impurities

- Natural organic additives to improve workability

Recommended for

Rising damp, Penetrating damp, Wind driven rain, Basement tanking, Chimneys, Salts, Flooding

Colour

Dark brown

Certifications

- Certified according to UNI EN 998-1:2016 as Renovating Plaster For Interior/Exterior Use

- Certified according to UNI EN 998-2:2016 as a Mortar with Guaranteed Performance - For External Use in Elements Subject to Structural Requirements.

- System 2+ Certified By TÜV Italy