Description

TERMORASANTE AEROGEL is a thermal bridging regulator, anti-condensation, anti-mold, highly breathable lime-aerogel thermal plaster.

Due to its high aerogel content, it is not only an outstanding thermal insulator - offering great insulation in a thin form factor, saving valuable space - but it also provides additional thermal benefits by reflecting the existing heat back into the living area.

The application of a thin (5 - 10 mm) coat can raise the surface temperature of walls by 3 to 5 °C. Thanks to its excellent heat reflectance, it creates a high thermal comfort in the room.

The plaster can be used in any type of building, new or old, for the construction as well as the renovation or refurbishment of older buildings with solid walls.

Why Aerogel?

Aerogel is a material that is 99.8% air. It is an extremely light material weighing about 1 kg/m³. It is also known as "solid air" or "blue smoke" due to its translucent nature and the way it scatters light.

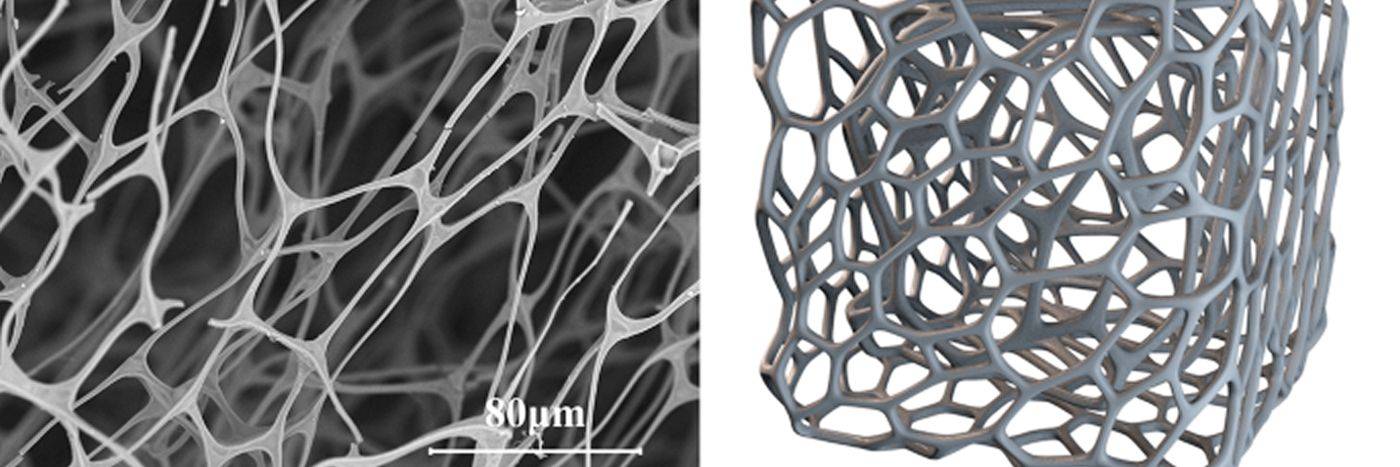

Despite its lightness, aerogel structurally is very strong. Its impressive load-bearing abilities are due to its microstructure, in which 2–5 nm spherical particles are fused together into a network of highly porous three-dimensional clusters measuring just under 100 nm.

Aerogel molecular structure

Aerogel is an extremely good thermal insulator because its three-dimensional clusters contain air pockets which almost nullify two of the three methods of heat transfer – conduction (aerogel being mostly composed of insulating gas) and convection (the microstructure prevents gas movement).

Demonstrating the aerogel's outstanding insulating properties: it protects the flower from the flame

Silica aerogel - used in our plaster - is an especially good thermal insulator because silica itself does not conduct heat.

Application

The video below highlights the most important points about the application of the plaster.

Plaster Composition

- Hydrated lime (air lime), with more than 90% calcium hydroxide

- NHL3.5 Natural hydraulic lime - desalinated white

- Nanotechnological aerogel

- Lightened amorphous silica

What to Use For?

Thermal insulation of buildings

Thermal bridging regulator

Anti-condensation

Anti-mould

Technical Specifications

Here are some key technical data.

Granulation | 0 - 1 mm (fine) |

Recommended layer thickness | 5 - 10 mm |

Consumption (kg / m² / cm thickness) | 3.5 kg / cm (or about 3 m² / bag) |

Thermal conductivity (λ) | 0.016 |

Equivalent thermal conductivity (λeq) * the combined effect of thermal conductivity, solar reflectance (SR) and infrared emittance (IE) | 0.010 |

Solar reflectance (SR) (ASTM C151549-09) percentage of heat reflected back into the room | 0.820 (82%) |

Infrared emittance (IE) (UNI EN 15976:2011) percentage of heat reflected as infrared radiation of high thermal comfort | 0.914 (91.4%) |

Water vapour permeability (UNI EN ISO 7783) | V1 (high) |

Liquid water permeability (UNI EN ISO 1062-3) | W2 (medium) |

Fire resistance (EN 13501-1) | class B – s2, d0 (what this means) |

Compressive strength ** according to other independent research papers, the compressive strength of various silica aerogels ranges between 0.8 - 1.1 N/mm² | NPD (not determined) |

Bag weight (kg) | 10 kg |

Physical appearance | White powder |

Plaster application temperature | 5 - 35 °C |

Colour

White