The Role of a Damp Proof Course

The primary role of a damp proof course (DPC) is to be a VAPOR BARRIER from the ground to prevent or minimize the excessive evaporation of water into the wall fabric, which over time develops into capillary action. This can be achieved by physical, chemical or electro/magnetic means. Several DPC technologies exist on the market, including non-invasive magnetic DPCs.

For solving rising damp long-term, fitting a damp proof course must be part of the rising damp remedial works. This does not have to be an invasive action - for older or listed buildings fitting a magnetic DPC is a hassle-free, non-invasive excellent option.

OTHER renovation actions - such as fitting drainage, having heating and ventilation, replastering with lime etc. - are NOT substitute for a damp proof course, and as a result, despite the improvements they make, they won't solve the rising damp problem. The technical reasons are discussed in detail here.

Several damp proof course technologies exist. These all differ in implementation, efficiency and longevity - here is a short development timeline and summary of each.

Types of Damp Proof Courses

The technology of damp proof courses has constantly evolved. Each DPC technology was a natural evolution over its predecessors, attempting to improve and simplify the application process, while also addressing some of the shortcomings of previous generations.

Original Physical DPCs

Based on written historic records, original physical DPCs date back to around the 1840s, possibly earlier. They were the first attempt to solve the problem of capillary rise, during times when buildings were generally erected onto the soil. After a few decades or centuries this resulted in rising damp, causing fabric decay, high humidity, health issues etc.

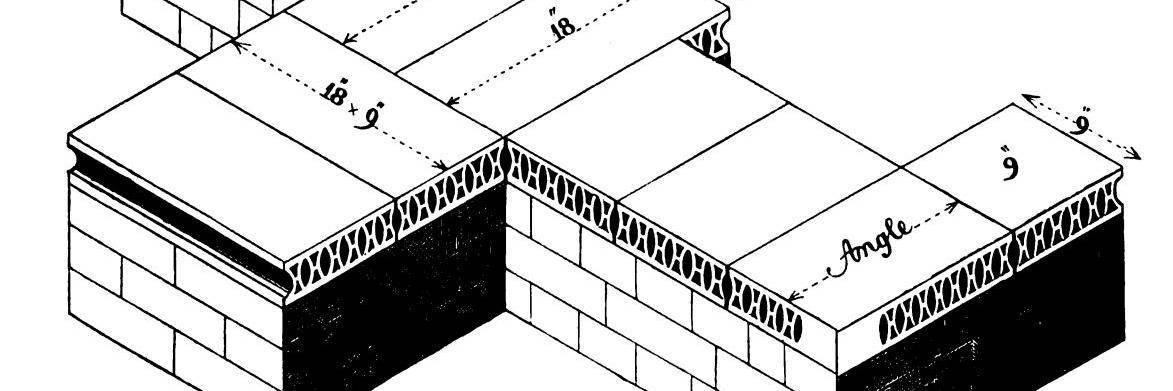

The most common materials used for damp proof courses in the Victorian age were slate bedded in cement, hot asphalt, sheets of lead, glazed bricks and vitrified stone-ware tiles.

As we already know today, these "original" damp proof courses lasted anywhere from a few decades to about a century, eventually failing as they aged, as the lifetime of a damp proof course is shorter than the life expectancy of a building.

Technical solutions had to be found to retrofit old buildings with new DPCs in order to keep rising damp in check.

Retrofitted Physical DPCs

The first attempt to repair aged, decayed DPCs that reached their end of life, was to add impervious (e.g. blue engineering) bricks to the base of the walls, or to cut the walls with a large chainsaw and drive stainless steel plates into the cut - a very invasive and labor intensive task.

Chemical DPCs

Technical advancements in chemistry made the retrofitting process simpler and less invasive by injecting waterproof chemicals into the walls. This reduced the workmanship to a few drilled holes every few inches. Nevertheless, the injection process was still fairly invasive, leaving permanent blemishes on buildings, while giving variable results, performing poorly on thick solid walls with rubble filled core.

Electroosmotic DPCs

Further technical research into molecular phenomena and a better understanding of electrokinetic phenomena made possible a newer, smarter, less invasive approach, by applying a small voltage to the walls through embedded wires.

But it was not all perfect, the main reasons why electro-osmotic DPCs failed over time were the corrosion or physical damage to the wires (as shown below), and more importantly, more recent findings have shown that in high salinity environments (e.g. old, porous, salt-laden walls) electro-chemical effects in the masonry rendered many of these systems ineffective.

Magnetic DPCs

Magnetic DPCs attempted to address the shortcomings of electroosmotic DPCs. New discoveries about Earth's energetic background, as well as advancements in radar and telecommunications technology, paired with some clever practical electronic engineering resulted in the elimination of the trouble-prone wires - providing a truly contactless, non-invasive and hassle-free solution to rising damp.

One magnetic DPC unit that looks like a small lampshade can cover the whole building, completely eliminating rising damp without invasive building work or damage to the fabric,

Longevity, Breakdown

Just like anything else, damp proof courses are also liable to aging and deterioration over time. Immense mechanical pressure, vibration, corrosive salts, microorganisms, frost action etc. are just some of the elements that cause damp proof courses decay over time.

The life expectancy of a damp proof course depends on the type of materials used and quality of the workmanship. Based on our experience, most DPCs if done correctly, can last anywhere between 50-100 years.

In the vast majority of cases one won't be able to assess the condition of a damp proof course by visual inspection, from its thin edge sticking out of the wall, with the other 95% of it being hidden in the wall. Instead, assessing the condition of the wall and plaster can give one clues about the condition of the DPC. As a rule of thumb: if the wall shows signs of rising damp above the DPC line, especially internal walls, with no other reason for this, then the damp proof course is probably compromised.

Here are some examples of damaged or broken down damp proof courses.

Free Download – Dampness in Old Buildings

Our 32-page PDF publication - DAMPNESS IN OLD BUILDINGS - written in plain English, with lots of pictures and among others, covers the following topics:

- An overview of main moisture sources affecting older buildings

- How you can diagnose dampness, visual signs presented with many pictures

- Damp proof course (DPC) solutions, their pros and cons

- Magnetic DPCs, the latest technical innovation

- Renovation guidelines for old buildings

- Top 5 renovation mistakes you must know about

- What lime plasters to use for renovation

- How to deal with condensation, mould... and much-much more